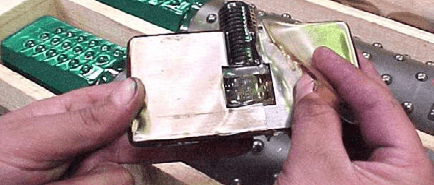

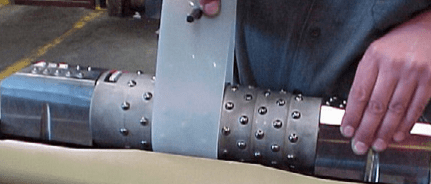

Undress A Redback™

To request more information, please fill out the form below and a Redback™ Drilling Tools & Manufacturing representative will be in touch with you as soon as possible.

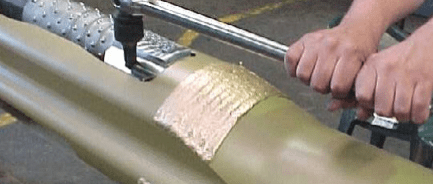

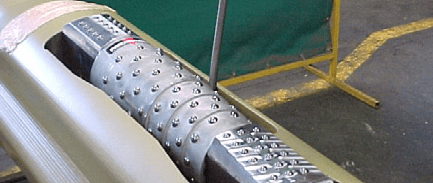

Dress A Redback™

To request more information, please fill out the form below and a Redback™ Drilling Tools & Manufacturing representative will be in touch with you as soon as possible.

Manual PDF

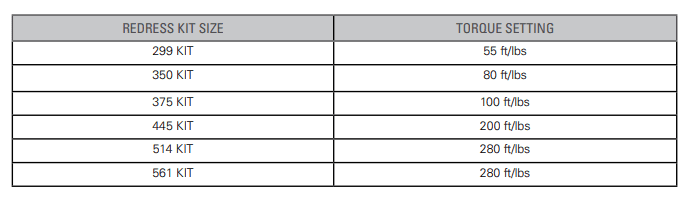

The Redback™ Field Operations Manual can be found with every Redback™ Roller Reamer and contains vital information to the operational maintenance of Redback™ components. Information such as assembly and installation instructions are included together with a basic troubleshooting guide.

For an electronic version of the document, please click the document below.