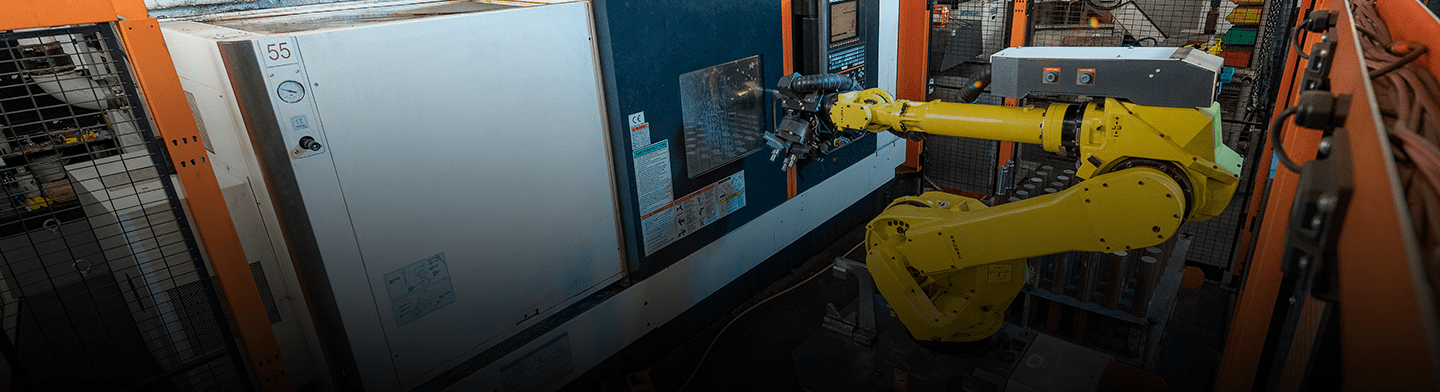

Redback™ Drilling Tools & Manufacturing has made a great leap toward automation of Redback™ parts production. They have acquired, tested and successfully integrated an automated machining centre that takes in raw material and returns finished products. The automated system has been designed by a Japanese manufacturer and uses a specialised robotic control arm to feed material into a High-Precision, High-Efficiency Integrated Mill Turn Center.

Unlike the carbide insertion robot which finishes a product off, the automated system starts with a batch of cut raw material from the saw. The material is loaded into a materials bay by operators and a production cycle is selected in the pre-programmed mill and turning centre. From here, the arm loads the raw material which can be as heavy as 28kg into the milling and turning centre for a machining. From the start to finish, the machining process requires no additional operator input leaving the operator to tend to other tasks. At the end of this, the robot arm unloads finished part and starts on the next part. This process continues as long as the machine is fed batches of raw material by operators when stock gets low and there are no errors.

Both the machines sit on top of a 600mm thick high density concrete slab with double mesh reinforcement to provide high levels of stability and vibration reduction. Currently, the automated system is producing Roller Reamer components of various sizes and has proven itself to be precise and accurate in full production mode. Moving forward, the manufacturer looks to further automate processes to remain competitive in the world of high tech and high precision machining.

For more information about the manufacturing facility and Redback™ products please contact us.