With the advent of more advanced machines into the South Australian workshop, an increasing number of Redback™ products are being made through automated processes. These processes are beyond the standard CNC machining as they encompass the use of two high tech robots acquired by SGS-Gearhart early to mid last year to assist with Redback™ component production. Each robot serves a different purpose so this article will be focused on the first of the two machines, the carbide insertion robot cell.

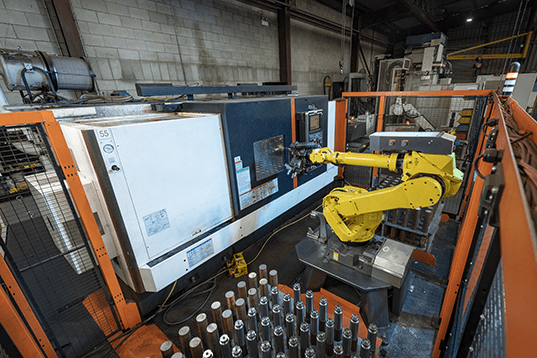

In early 2018, the carbide insertion robot cell was designed and delivered to Redback™ Drilling Tools & Manufacturing in Adelaide by an Australian industrial equipment supplier. The two manipulator robotic cell was custom designed and built with the intention of reducing the amount of manual labour needed to insert carbide into roller reamer redress kit components. Carbide insertion is a slow, precise and highly repetitive task which is why it was a perfect use case for the robotic arms.

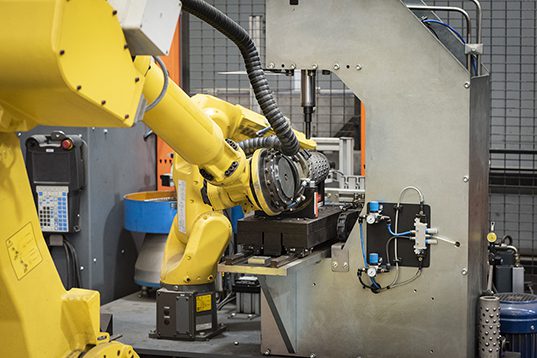

The robot cell consist of two independent manipulators, a small manipulator for picking up and holding tungsten carbide and a large arm that loads parts for carbide insertion. These two manipulators work in tandem to align the carbide pieces to the holes of the parts ready for pressing by use of an automatic press. Control of the machines is achieved through the use of a programming computer installed onto the exterior of the cell. This allows for changes to be made when required and new work cycles to be loaded when necessary.

Since the acquisition of the carbide insertion robot cell, the machine has been optimised to press in carbide at a rate equal to that of previous manual operations. The machine works accurately, and continuously for a long period of time until halted by an operator or a work cycle has been completed. This has increased the amount of available work force to tend to other components of the Redback™ Roller Reamers.

For more information about the manufacturing facility and Redback™ products please contact us.