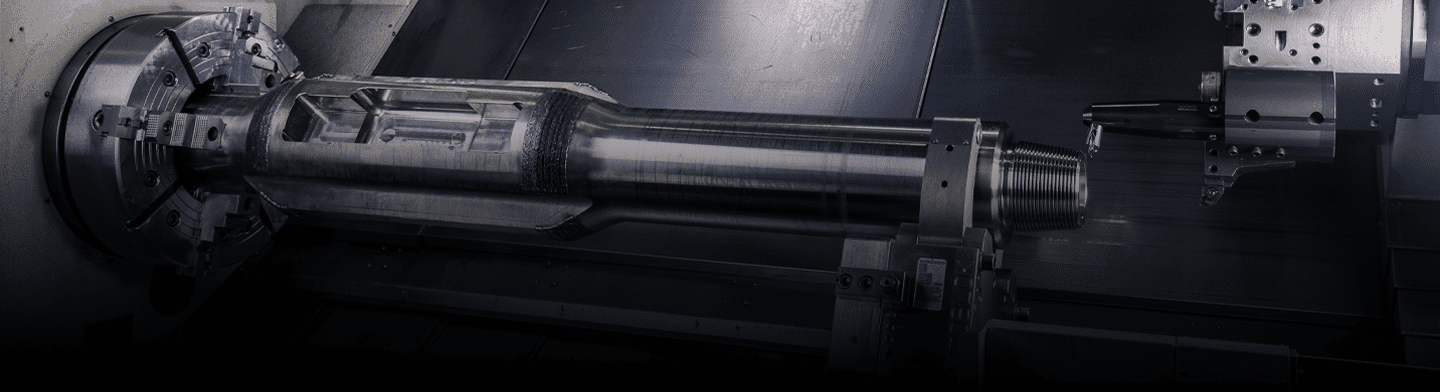

The Redback™ Roller Reamer features a patented wedge lock cutter retention system which provides performance reliability and dependability.

Roller Reamers

As Roller Reamer designers and manufacturers, Redback™ Drilling Tools & Manufacturing produce a range of roller reamers for the oil and gas drilling industry, designed to improve drilling efficiency and reduce costs.

Featuring a pressure equalised lubricated bearing system, the cutters ensure effective operation in high pressure, down hole environments. The cutters’ seals prevent mud and cuttings from entering the bearings while retaining lubricant within the bearing faces meaning additional attainable revolutions.

The low torque point of stabilisation allows the Roller Reamer cutters to roll around the hole, reducing stick slip and vibrations. By reducing vibrations, the Redback™ Roller Reamers increase the mean time between failures (MTBF) of other bottom hole assembly (BHA) components.

Unlike fixed blade stabilisers, the Roller Reamer causes less hole wall damage. The stepped profile only opens the hole to the Reamer’s dressed diameter and removes ledges and mini doglegs from the borehole. The smoother wall profile significantly aids the drilling, logging, coring, and casing running processes. The combined features of the Roller Reamer reduce risk throughout the drilling process.

Roller Reamer Specifications - Key Product Details

Improved Bit Weight Transfer Assists

By improving the bit weight transfer, together with torque reduction and stick slip increases the constant energy available at the bit – the weight ratio factor. Removing the peaks from the constant energy adds life to tri cone bit bearings and reduces PDC cutter/TCI tooth breakage. As Stick slip release can result in high string RPM, reducing the spikes decreases incidents of cutter face damage and drill bit reverse rotation.

Reduce Trip Times Through Tight Sections and Ledge Removal

By removing tight sections and ledges in the reamed hole, the trip times in and out of the hole are significantly reduced. Patented bi-directional and back reaming cutters facilitate the reaming through tight spots when tripping out of the hole. Typically, this can be done only where rigs are equipped with top drive equipment. Improved borehole profile also reduces the frequency of stuck pipe incidents and thereby fishing operations.

Simple Access Through Ledge Removal

The removal of ledges assists wire line logging tools and casing/liner down hole, significantly reducing running times and instances of getting stuck. With LWD tools, stick slip vibration reduction allows noise reduction and improved MTBF.

Reduction of Stick Slip

Torque can be detrimental to quality core collection. The reduction of stick slip allows more constant barrel rotation and reduced vibrations increasing coring performance.

Optimised Cutting Action

The hard formation cutter profile optimises the cutting action for the opening of under gauge hole and the removal of stringers and ledges typically created by direction change in the borehole.

Roller Stabilisation

The stabilisers allow longer reamers with full gauge hole wall contact. Under gauge rollers to simulate fixed blade stabiliser dimensions are also available. A maintenance manual is included with each set of cutters. This manual gives full details on changing the cutter cartridges.

Request More Information

To request more information, please fill out the form below and a Redback™ Drilling Tools & Manufacturing representative will be in touch with you as soon as possible.

Download Documents

The Redback™ Field Operations Manual can be found with every Redback Roller Reamer and contains vital information to the operational maintenance of Redback™ components. Information such as assembly and installation instructions are included together with a basic troubleshooting guide.

Frequently Asked Questions

To request Technical Data Sheets, please fill out the form below and a Redback™ Drilling Tools & Manufacturing representative will be in touch with you as soon as possible.

1. Can I run the roller reamer in the drilling assembly?

Yes, historically the use of the roller reamers was to just run it in a clean out or wiper trip assembly after the section had been drilled. To gain the most benefit out of running a roller reamer, this should be run as part of the drilling assembly which will aid the drilling performance while ensuring the hole is kept in good condition and provide an easier trip out of the hole. Drilling assemblies including a roller reamer significantly reduces the likelihood of requiring a further clean out/wiper trip. Reaming the hole while drilling will make it easier to run the casing first time and without having the cost of an additional run

2. Where can I place the Roller Reamer?

The placement options are not limited when looking to run the roller reamer. It can either be replacing a specific stabilised point in the assembly or even running a complete assembly with only Roller Reamers instead of stabilisers. We have a very experienced team who can assist and provide you with the required information on where best to position the Roller Reamers to optimise the performance. Placement can be higher up in the assembly with standard steel body tools and further flexibility is provided through the option of running Non-Mag roller reamer bodies that can be placed lower down into the assembly Specialised designs that allow for real-time communication through the bodies are available. These are specific to the Directional Drilling companies

3. Can it be run with other vibration reducing tools?

Yes, the Redback™ roller reamers have regularly been run with down hole tools that target the reduction of stick-slip vibration. The added benefit of the roller reamer is that it provides 3 Points of stabilisation, reduces torque and subsequent vibration while also being able to condition the hole and ream any ledges, transition areas and possible under gauge hole