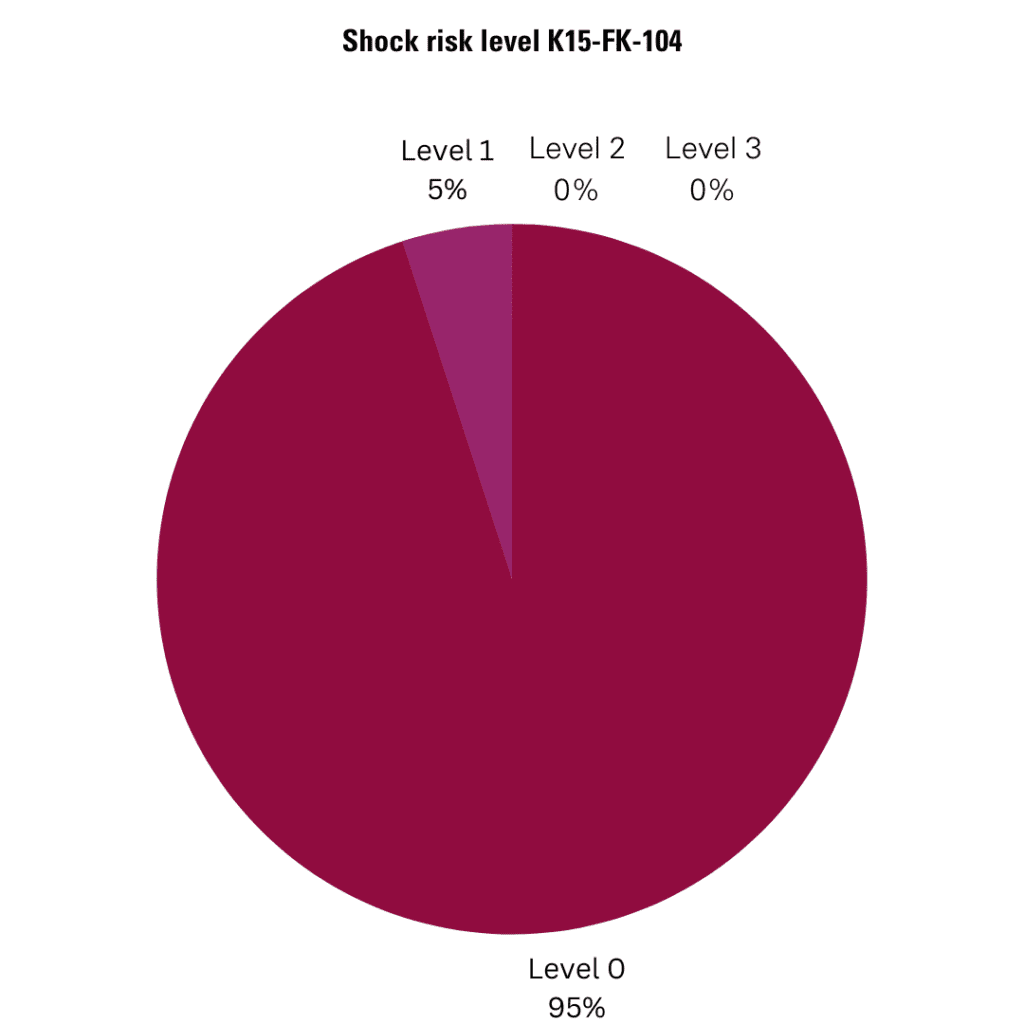

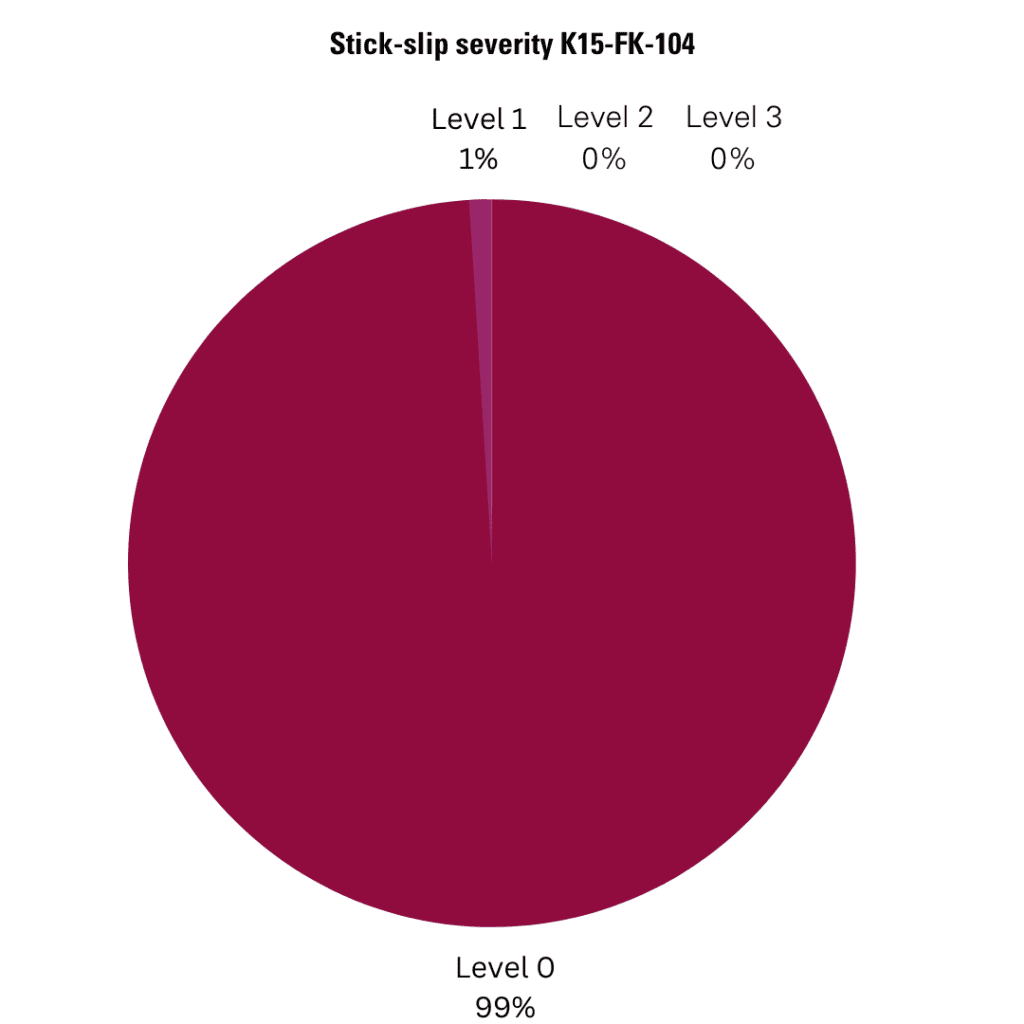

Using the MWD Tool, the levels of stick-slip and shocks were measured with and without the aid of the Redback™ Roller Reamer to compare and contrast the vibration logs between the two runs.

Drilling through the Hardegsen, Detfurth and Volpriehausen formations, the results were found to be much more favourable in the run where it was aided by the Redback™ Roller Reamer.

The vibration levels recorded during the section were the lowest experienced in the four well drilling campaign.

The low levels of vibration show the significant improvement in the drilling dynamics by replacing the fixed blade stabilizers in the assembly with the Roller Reamers

For more information on how Redback™ Drilling Tools & Manufacturing can optimise your operations contact us today