With a commitment to excellence and a focus on delivering cutting-edge solutions, Redback™ Drilling Tools & Manufacturing has established a strong presence in PNG, partnering with major mining companies and exploration firms to enhance their drilling capabilities. By providing state-of-the-art drilling tools and a comprehensive suite of services.

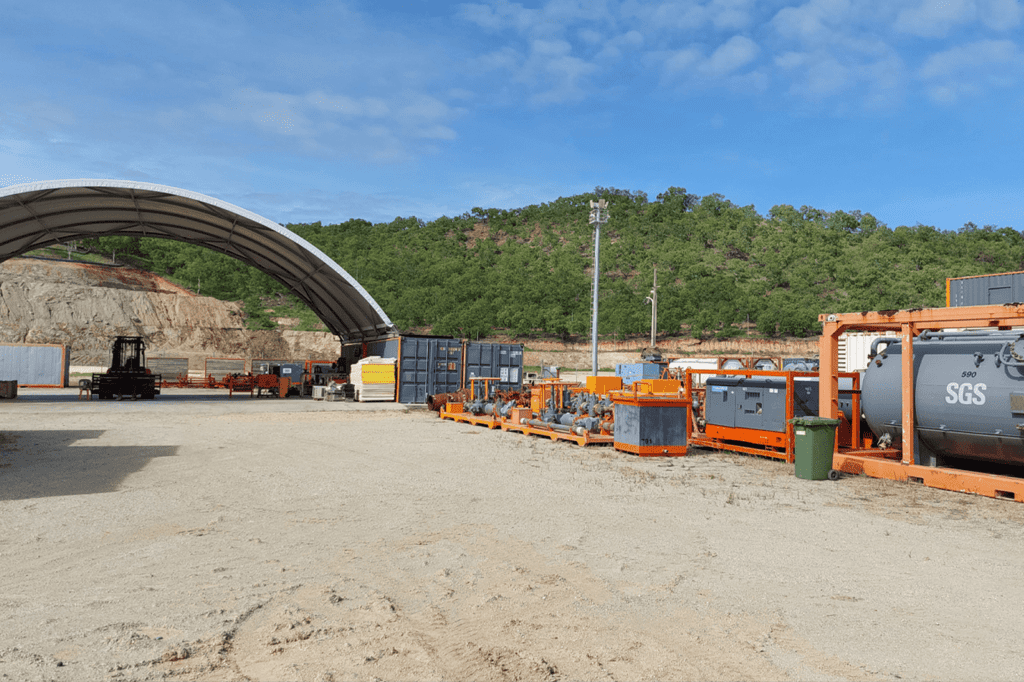

As a proud member of the SGS Group, Redback™ Drilling Tools & Manufacturing possesses a unique advantage through our global network. This advantage enables us to deliver not only a comprehensive range of cutting-edge drilling solutions but also facilitates connections to a diverse array of upstream and industry services. Our primary objective is to support your operations throughout the entire lifecycle, ensuring seamless efficiency and success.

One of the key factors that sets Redback™ apart is our unwavering commitment to quality. We adhere to the highest standards in the design, manufacturing, and delivery of our drilling tools. Redback™’s product range includes a wide variety of drilling equipment, such as drill bits, reamers, stabilizers, and hammers, among others. These tools are engineered to withstand the most challenging drilling conditions, ensuring optimal performance, durability, and efficiency.

Mining companies and exploration firms in PNG have experienced improved drilling efficiency, reduced operational costs, and enhanced overall performance. Alongside client benefits, we are also creating job opportunities for skilled workers, contributing to the growth and development of the local workforce. By transferring knowledge and expertise, we are committed to upskilling local professionals and promoting the long-term sustainability of the drilling industry in PNG.

We have a key emphasis on research and development in PNG continuously investing in advanced technologies, materials, and manufacturing processes to develop innovative drilling solutions. By staying at the forefront of industry advancements, we can provide tools that deliver superior performance, minimize downtime, and maximize productivity.

Our competitive edge stems from harnessing the vast expertise and global connections of the SGS Group. This enables us to deliver an integrated approach tailored to your specific needs, whether it’s cutting-edge drilling solutions, extensive industry services, or steadfast support at every stage. With Redback™ Drilling Tools & Manufacturing, you gain access to a comprehensive suite of services coupled with unmatched industry insights. Count on us as your trusted ally, supporting your business ventures and driving sustainable growth in PNG’s energy industry.

With an extensive range of services in PNG, contact us today to find out how we can benefit your operations.